Heritage Plaster Services – Craftsmen in Plaster

Heritage Plaster Services are specialists in restoring, repairing, and creating all aspects of traditional decorative plaster and mouldings.

Heritage Plaster Services can supply plaster cornice, coving or ceiling roses, whether it’s from our exquisite range of standard classical Victorian, Georgian or Regency period designs or to your bespoke vision.

We are proud to have worked with

Heritage Plaster Services – Craftsmen in Plaster

Heritage Plaster Services are specialists in restoring, repairing, and creating all aspects of traditional decorative plaster and mouldings.

Heritage Plaster Services can supply plaster cornice, coving or ceiling roses, whether it’s from our exquisite range of standard classical Victorian, Georgian or Regency period designs or to your bespoke vision.

Whatever period building you have, you can be sure your work will be accomplished by experts, using the most appropriate methods and materials. Heritage Plaster Services has 30 years of experience and research which informs our knowledge of traditional fibrous plastering and decorative plaster techniques both old and new.

To ensure your restoration project is faithful to the original design our aim on every project is to retain the vision of the architects, designers and artists who came before us, employing their techniques where possible, and incorporating new technology where appropriate.

Our fibrous plaster specialists will handle your project from first plans right through to completion. Our skilled designers and expert artisans can create handmade plaster mouldings for any project, big or small, from the faithful recreation of classic styling to modern visionary designs.

Featured Services

Modelling

Clay Modelling is used to reproduce or create architectural ornamental decorations and is considered an art form which dates back to pre-history.

Bespoke Ceilings

The Tudor and Jacobean periods (1485 – 1625) marked the evolution away from the medieval styles of building toward more sophisticated structures with classicised decoration.

Architectural External Mouldings

Architectural external mouldings are just as important to the exterior of buildings as to the interior, from the simplest sand & cement moulding architrave to the grandest entablature.

Lime Plaster

Lime Plaster Conservation Restoration. Virtually all old buildings were constructed using lime, which was used in conjunction with many materials according to regional difference.

FREE Friendly Expert Advice

FREE Personlised Quote

Your Own Personal Project Manager

Heritage Plaster Mouldings

- Featured Roses

- Featured Cornices

CR4 Ceiling Rose

CR4 Ceiling Rose is a Large fibrous ceiling centrepiece comprised of several rings.

Dimensions: CR3 620mm and CR4 900mm

Heritage Plaster Services offer a supply and installation services for all products. Please feel free to contact our Sales Team on 01708 252400 or by email sales@hpslondon.co.uk for more information. We would be happy to assist you select an appropriately sized and styled mouldings for your project whatever the scale or type of project you have in mind.

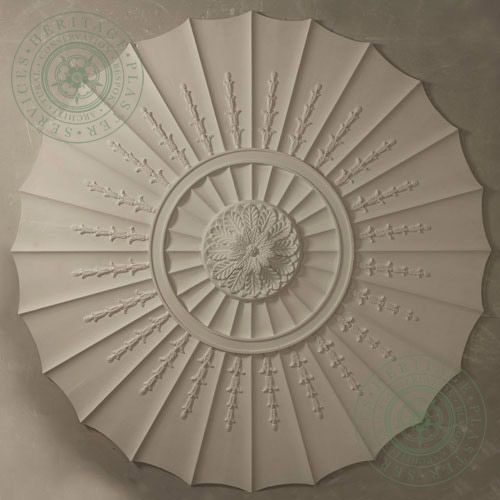

CR9 Ceiling Rose

CR9 Ceiling Rose is an Adams design very large ceiling centerpiece with large open flutes overlaid with fine leaf enrichment with ornate central boss. Dimensions: 1290mm

Heritage Plaster Services offer a supply and installation services for all products. Please feel free to contact our Sales Team on 01708 252400 or by email sales@hpslondon.co.uk for more information. We would be happy to assist you select an appropriately sized and styled mouldings for your project whatever the scale or type of project you have in mind.

CR14 Ceiling Rose

CR14 Ceiling Rose is a large Adams design oval ceiling centrepiece with plain open flutes, small fluted enrichment and ornate central boss. Dimensions: 1300mm/910mm

CR19 Ceiling Rose

CR19 Ceiling Rose is a medium rose with wheat sheaf enrichment and raised beeded patra to outer banding. This fibrous plaster rose is a standard plaster moulding from the Heritage Plaster range. Heritage Plaster Services offer a supply and installation services for all products. Dimensions: 658 surround 758mm

Please feel free to contact our Sales Team on 01708 252400 or by email sales@hpslondon.co.uk for more information. We would be happy to assist you select an appropriately sized and styled mouldings for your project whatever the scale or type of project you have in mind.

CR20 Ceiling Rose

CR20 Ceiling Rose is a large ornate fibrous plaster moulding with high relief flower designs and water leaf. The CR20 also has an outer leaf section that can increase size and add enrichment. Dimensions: 760mm (910mm with outer leaf enrichment)

CR24 Ceiling Rose

CR24 Ceiling Rose is a medium oval leaf rose with sinuous leaf design and ornate central boss. The CR24 Ceiling Rose is a standard fibrous plaster moulding. Dimensions: 600mm/415mm

Heritage Plaster Services offer a supply and installation services for all products. Please feel free to contact our Sales Team on 01708 252400 or by email sales@hpslondon.co.uk for more information. We would be happy to assist you select an appropriately sized and styled mouldings for your project whatever the scale or type of project you have in mind.

CR30 Ceiling Rose

CR30 Ceiling Rose is medium centrepiece made up of multiple fibrous plaster casts fitted separately to form the whole floriated piece. The design is made up of alternating acanthus and narrow lillys with stems and plain leaves to central boss section. Dimensions: 785mm

Heritage Plaster Services offer supply and installation services for all products. Please feel free to contact our Sales Team on 01708 252400 or by email sales@hpslondon.co.uk for more information. We would be happy to assist you to select an appropriately sized and styled ceiling plaster mouldings for your project whatever the scale or type of project you have in mind. Our suggested cornice design to go with the CR30 loose leaf ceiling rose would be the HPS59 Cornice

CR37 Ceiling Rose

CR37 Ceiling Rose is a medium fibrous plaster centrepiece made up of multiple casts fitted separately to form this ceiling piece. This decorative design is comprised up of alternating acanthus leaves and flowers with stems and plain leaves to a central boss section. Dimensions: 840mm

Heritage Plaster Services offer a supply and installation services for all products. Please feel free to contact our Sales Team on 01708 252400 or by email sales@hpslondon.co.uk for more information. We would be happy to assist you select the appropriately sized and styled mouldings for your project whatever the scale or type of project you have in mind.

HPS12 Plain Georgian Drip Cornice

HPS12 Plain Georgian Drip Cornice is a standard fibrous plaster moulding hand manufactured by Heritage Plaster Services.

| HPS12 Product Details | |

|---|---|

| Ceiling Projection | 172mm |

| Wall Height | 185mm |

| Length | 3000mm |

HPS42 Enriched Cove "Portland"

HPS42 Enriched Cove "Portland"is an upright leaf detailed cove with bead enrichment to the top member sitting beneath the cyma recta. Originally taken from an existing moulding in the Portland place of central London on the Howard De Walden estate.

| HPS42 Product Details | |

|---|---|

| Ceiling Projection | 170mm |

| Wall Height | 187mm |

| Length | 3000mm |

HPS73 Plain Run Cornice

HPS73 Plain Run Cornice is a large profile with three square steps to the ceiling and wall line.

| HPS73 Product Details | |

|---|---|

| Ceiling Projection | 150mm |

| Wall Height | 135mm |

| Length | 3000mm |

HPS77 Cornice "Sylvie 1"

HPS77 Cornice "Sylvie 1" is a fibrous plaster cove profile with fine members to the wall and ceiling line and a small egg and dart enrichment to the bottom member. HPS77 Cornice is manufactured in 3 metre lengths.

| HPS77 Cornice Product Details | |

|---|---|

| Ceiling Projection | 120mm |

| Wall Height | 105mm |

| Length | 3000mm |

HPS103 Cornice "Wheelers"

HPS103 Cornice "Wheelers" is a Victorian plain run fibrous plaster profile with a large cove and extended ceiling plate made up of cyma and half round sections. HPS103 Cornice was originally taken from an existing moulding in the Chingford area of North East London. Available in 2 differing sizes to allow continuity between varying ceiling heights.

| HPS103 Product Details | |

|---|---|

| Ceiling Projection | 178mm |

| Wall Height78 | 78mm |

| Length | 3000mm |

HPS35 Cornice Classical Fibrous Cornice

HPS35 Cornice is an adaptation of a classic Georgian egg and dart cornice, note the elongated throat to the drip. The leaves to the top member are hand applied as separate plaster elements thus allowing a far higher depth to this enrichment that creates a stunning visual effect, whilst also offering the option of leaving this top member free of ornamentation.

HPS35 Cornice is manufactured in 3 metre lengths.

Heritage Plaster Services offer a supply and installation services for all products.

Please feel free to contact our Sales Team on 01708 252400 or by email sales@hpslondon.co.uk for more information. We would be happy to assist you select the appropriately sized and styled mouldings for your project whatever the scale or type of project you have in mind.

| HPS35 Cornice Product Details | |

|---|---|

| Ceiling Projection | 205mm |

| Wall Height | 128mm |

| Length | 3000mm |

HPS64 Enriched Cornice

HPS64 Enriched Cornice is a large fibrous plaster moulding with double enrichment details consisting of wheat sheaf design to the ceiling plate and leaf with bead and reel to the wall member, a large cove section lying between the two enrichments.

This HPS64 enriched ceiling plate cornice moulding is manufactured in 3 metre lengths.

Heritage Plaster Services offer a supply and installation services for all products.

Please feel free to contact our Sales Team on 01708 252400 or by email sales@hpslondon.co.uk for more information. We would be happy to assist you to select the appropriately sized and styled mouldings for your project whatever the scale or type of project you have in mind.

| HPS64 Product Details | |

|---|---|

| Ceiling Projection | 355mm |

| Wall Height | 160mm |

| Length | 3000mm |

HPS65 Cornice

HPS65 Cornice is a highly ornate fibrous plaster modillion block design based upon the Corinthian order. It is comprised of an enriched block and patra, followed by a double leaf enrichment to the top and bottom members, with an egg & dart and dentil ornamentation, all finely proportioned.

Attention would be drawn to the correct setting out this ornamentation at mitre junctions.

HPS65 Plain Run Square Cornice is manufactured in 3 metre lengths.

Heritage Plaster Services offer a supply and installation services for all products.

Please feel free to contact our Sales Team on 01708 252400 or by email sales@hpslondon.co.uk for more information. We would be happy to assist you select an appropriately sized and styled mouldings for your project whatever the scale or type of project you have in mind.

| HPS65 Cornice Product Details | |

|---|---|

| Ceiling Projection | 237mm |

| Wall Height | 226mm |

| Length | 3000mm |

Heritage Plaster Projects

-

Albert Court Mansions - Restoration

Project Details Location:47 Albert Court Mansions, London Project Type: Restoration, Bespoke Mouldings

-

Sloane Street - Ceiling Replication

Project Details Location:Sloane Street, London Project Type: Bespoke Ceiling

-

Wetherby Place

Project Details Location:South Kensington, London Project Type: Bespoke Ceiling, Bespoke Moulding

-

Cavendish Avenue

Project Details Location:Cavendish Avenue, London Project Type: Restoration, Bespoke Moulding

-

Soho House, Dean Street

Project Details Location:Dean Street, London Project Type: Restoration, Bespoke Moulding, lime plastering

-

Everyman Theatre, Cheltenham Town Centre

Project Details Location:Cheltenham Project Type: Restoration

-

Maison Colbert

Heritage Plaster Services supplied and installed a varied array of bespoke plaster mouldings to the interior, including the niches and alcoves, along with various panelled designs and the bespoke inner entrance way. As well as the interior works we also supplied and installed the large corbels to the exterior shopfronts. Profile: The site, in an...

-

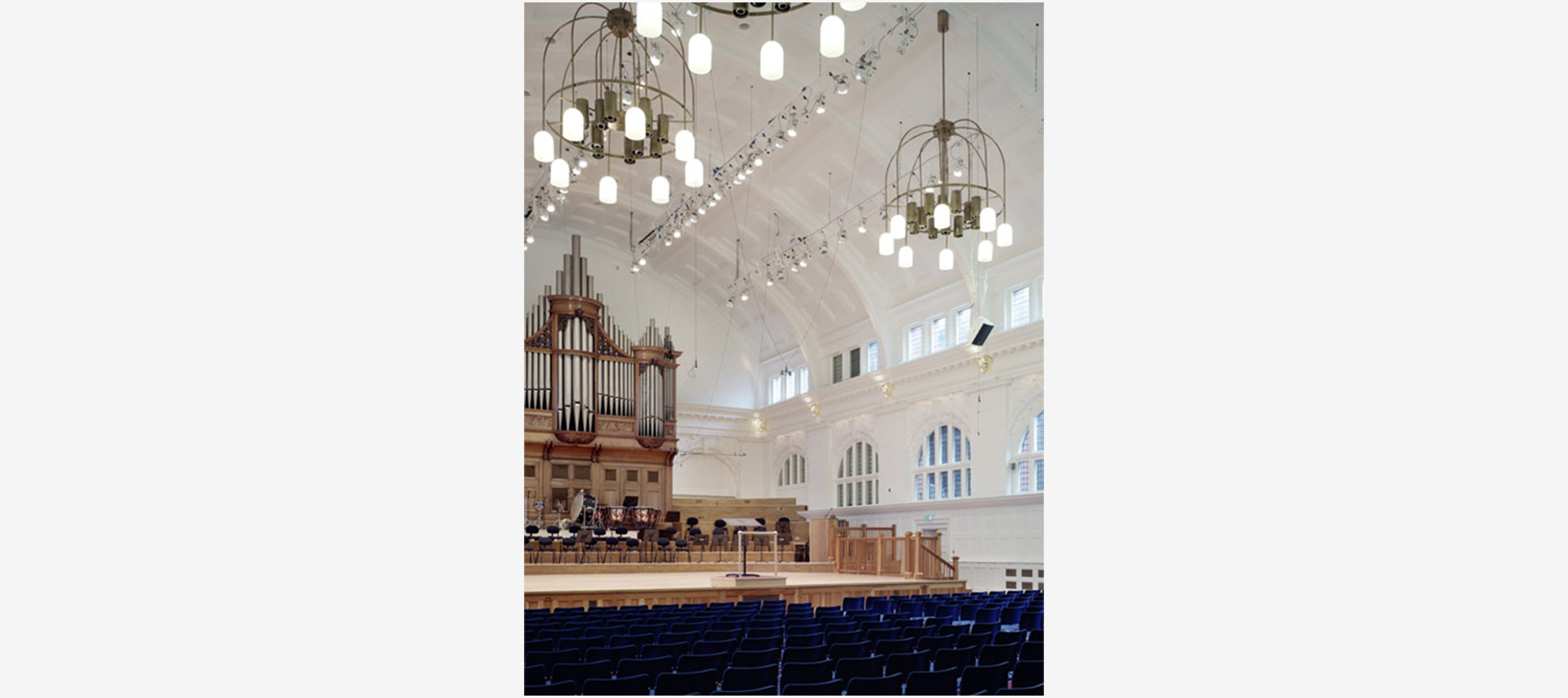

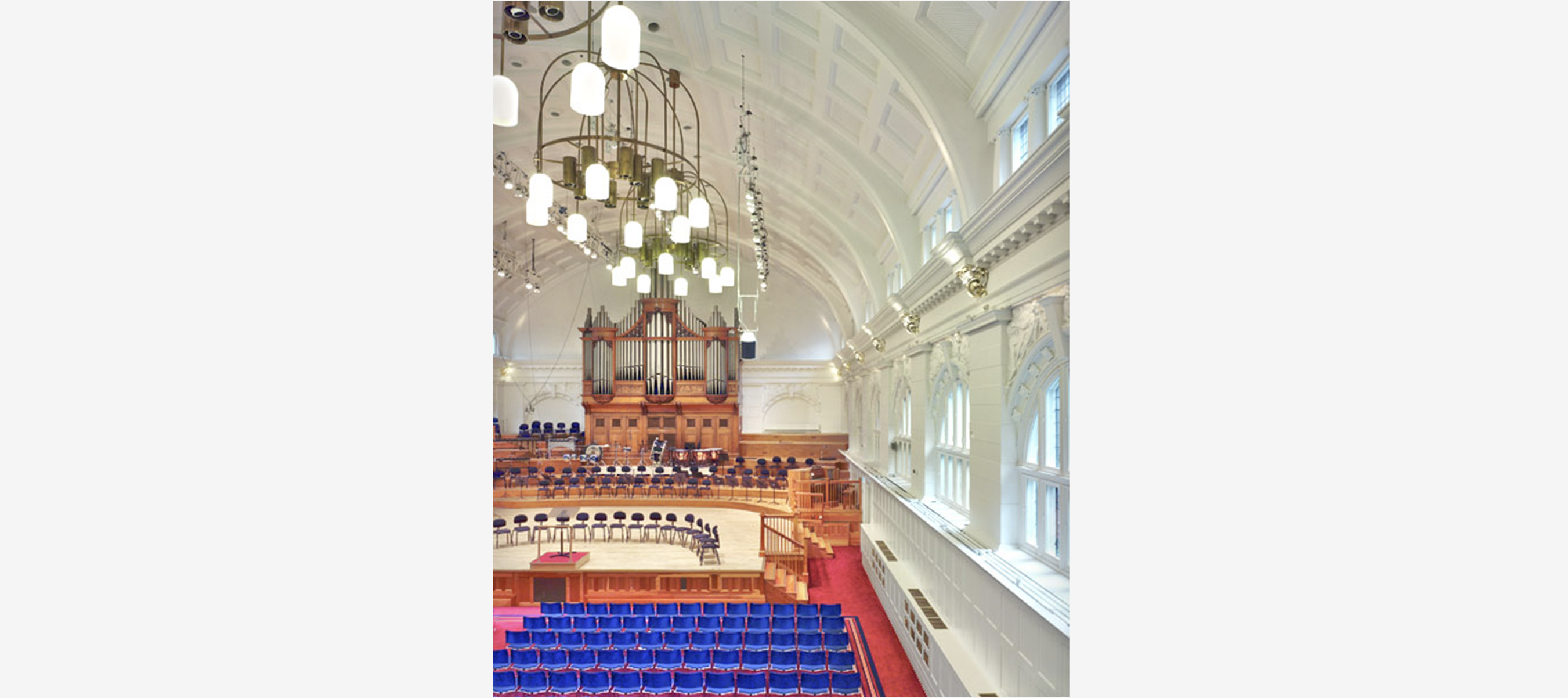

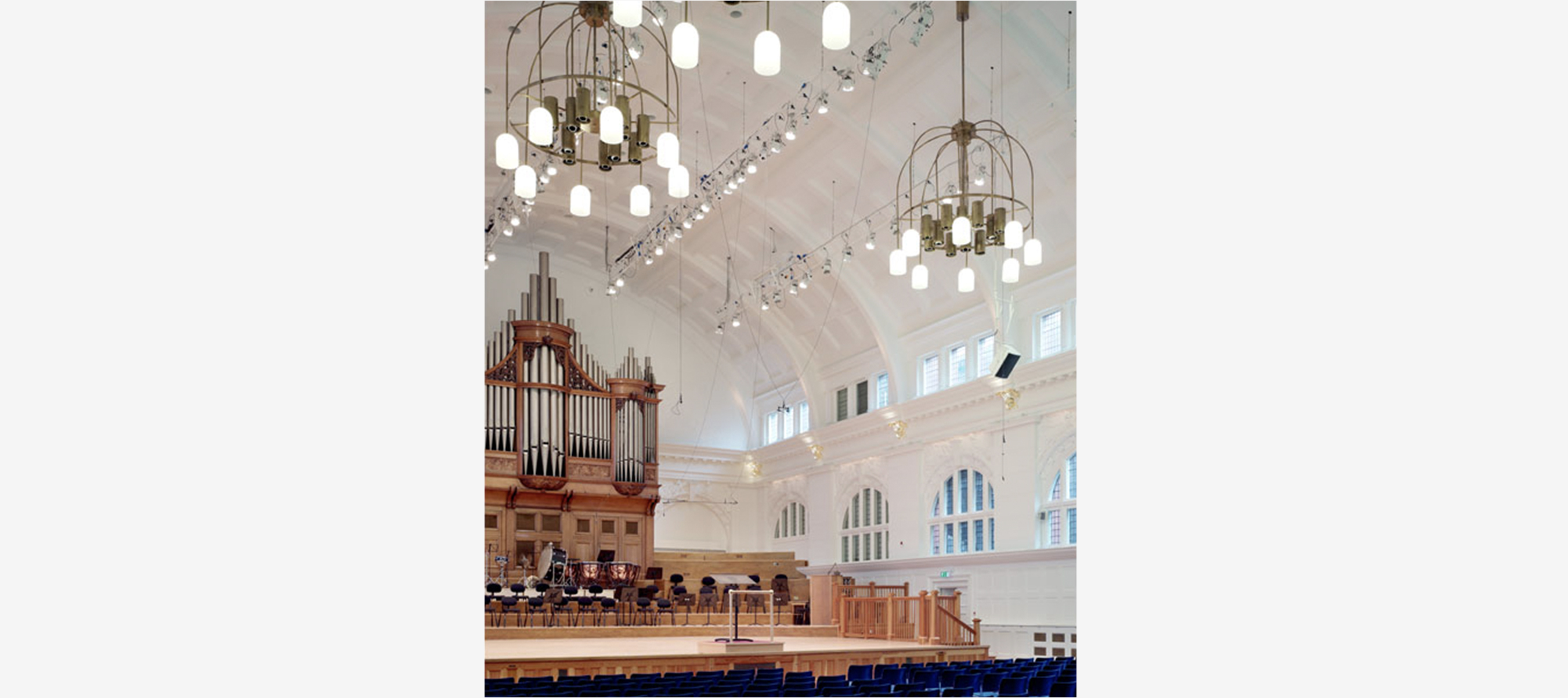

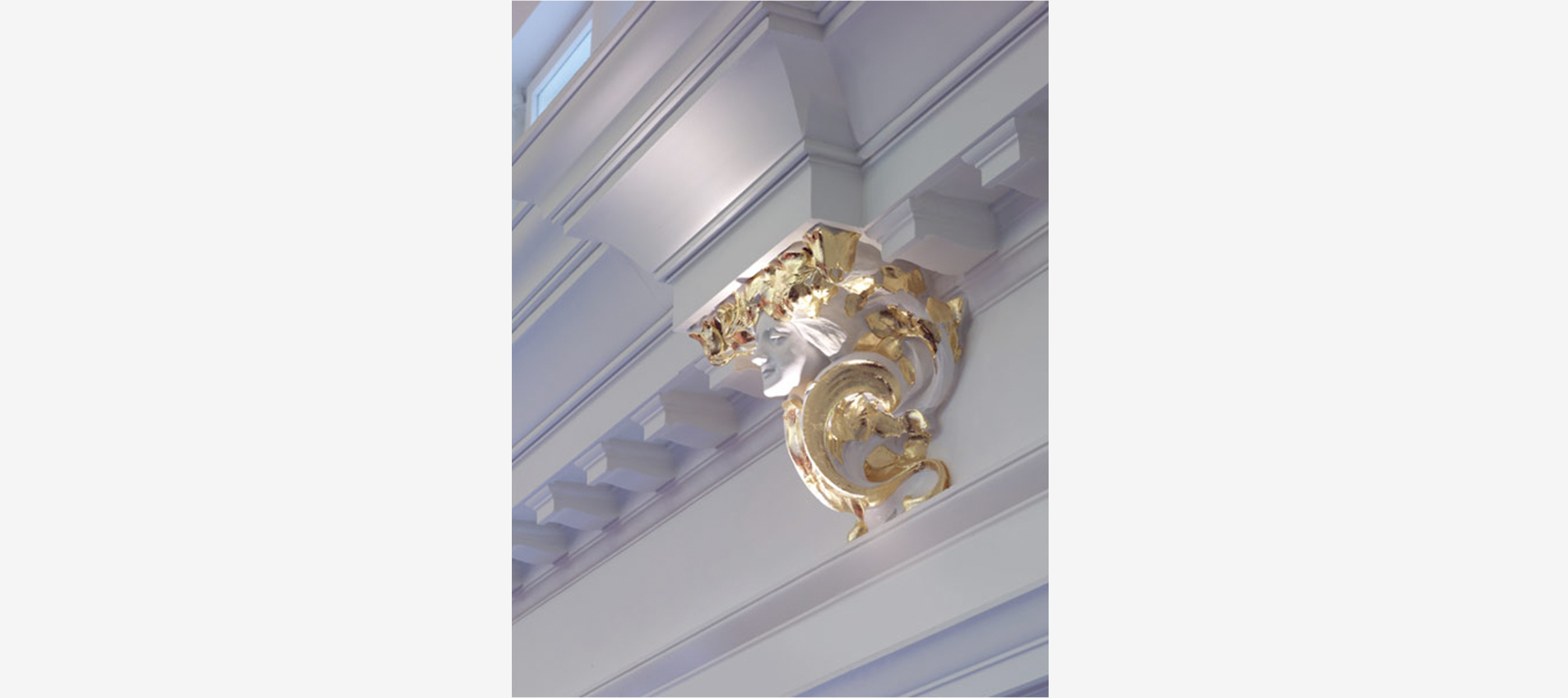

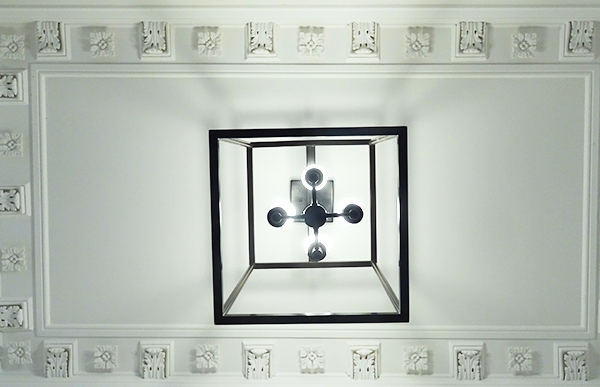

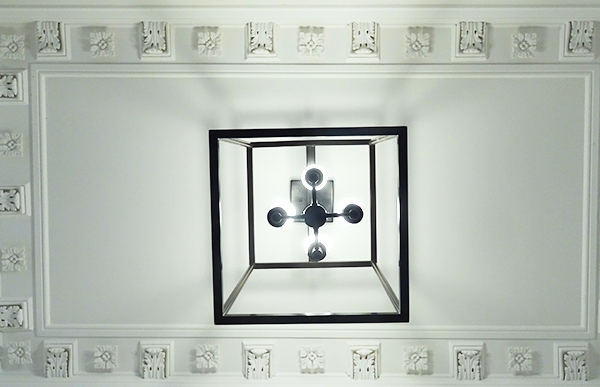

Royal College of Music, London

Project Details

Location:

Kensington, London SW7 2BSProject Type:

Restoration, Bespoke MouldingBack to ProjectsThe purpose of these works was to allow the full renovation of the main concert hall.

The original plaster casts/mouldings that made up the panelled ceiling had, by the simple passage of time, deteriorated and had become dangerous in their fragility.

The entire ceiling area required to be removed and replaced. The new panels that were to replace the old ceiling in its entirety were designed to replicate the original ceiling in shape and general form, but at the same time to allow the introduction of modern sound, light and heating systems.

These works therefore consisted of the manufacture of moulds, the casting of new panels from these moulds, and the site assembly of these panels, as separate units to make up the complete ceiling.

The design of these moulds also allowed for the incorporation of air conditioning nozzles, access panels for maintenance purposes, access panels for lighting, sound and scenery pulleys, and a complete set out of acoustic panels as devised by Cole Jarman Associates.

As a result of these tests alterations to the panel designs were made, with the inclusion of different size holes to the panel faces, back boards, panel sizes and panel depth sizes. To allow for the various acoustic panel requirements, a.c. nozzles and access panels, 7 different moulds were needed.

Once all items were manufactured out of Casting plaster, with Hessian scrim and timber lathing laid into the plaster as reinforcement, they were assembled on site as to the ceiling layout plan.

One important innovation was the use of Jesmonite as the casting material for the acoustic panels and the doors to the access hatches, this material being superior in purpose for these items.

Once the new ceiling was in place, the only remaining items of the original ceiling, being the large elliptical beams running from West to East Elevations, were made good and repaired as required. Large sections of these having to be removed during the installation of the new air conditioning units, new moulds, left and right handed were manufactured to replace these sections.

New wiring and trunking has been applied to the top of the mid-level plaster block cornice. In order to block the site line to this wiring from the hall an additional front member has been applied to this cornice.

Whilst in the process of fitting this new moulding, we discovered that the original cornice, through age, had become loose on its original fixings.

In order to repair and refit this cornice, bespoke steel brackets were manufactured and fitted to the wall behind the cornice by the use of chemical fixings and bolts. Once fitted to the wall, the brackets projected across the top of the cornice which was then secured to these brackets by a system of metal ties and plaster/Hessian wads.

Through the preceding years general repairs had been made to the lower level plaster mouldings. Many of these were of a limited or short term standard, in fact in many cases tape had been applied to cover areas of damage, this tape then being painted over to disguise much of the damage.

Lighting and sound equipment had also been fitted in place on and ad hoc basis, these again have all been removed with all damage being repaired in situ.

-

-

Trinity Street, London

Project Details Location:Kensington, London SE1 Project Type: Bespoke Mouldings, External Mouldings, Conservation & Restoration

-

Trinity Square, London

Project Details Location:London EC1 Project Type: Bespoke Moulding Grade II listed Property

-

Chester Street Bespoke Ceiling, London

Project Details Location:Chester Street, London Project Type: Bespoke Ceiling

-

Burlington Arcade, London

Project Details Location:Mayfair, London W1J 0QJ Project Type: Conservation & Restoration

-

Hereford Square, London

Project Details Location:South Kensington, London SW7 Project Type: External Mouldings, Bespoke Moulding

-

Mari Vanna Restaurant, Knightsbridge – Bespoke Fibrous Plaster Ceiling

Project Details Location:Knightsbridge, London SW1X 7PJ Project Type: Bespoke Ceiling, Bespoke Moulding

-

Trinity Square Skylight, London

Project Details Location:London EC3N 4AJ Project Type: Conservation & Restoration Grade II* Listed

-

Albert Court Mansions, London

Project Details Location:Albert Court Mansions, London SW7 Project Type: Bespoke Ceiling, Bespoke Moulding

-

Headstone Manor, London

Project Details Location:Harrow, London HA2 Project Type: Lime Plaster

-

Phillimore Gardens, London

Project Details Location:Kensington, London Project Type: External plastering

-

Hitherbury House Development, Guildford GU2

Project Details Location:Guildford, GU2 Project Type: Illuminated Cornice

-

Institute of Chartered Accountants in England & Wales, Moorgate Place

Project Details Location:Moorgate, London EC2R 6EA Project Type: Conservation & Restoration Grade II listed property

Heritage Plaster Projects

-

Albert Court Mansions - Restoration

Project Details Location:47 Albert Court Mansions, London Project Type: Restoration, Bespoke Mouldings

-

Sloane Street - Ceiling Replication

Project Details Location:Sloane Street, London Project Type: Bespoke Ceiling

-

Wetherby Place

Project Details Location:South Kensington, London Project Type: Bespoke Ceiling, Bespoke Moulding

-

Cavendish Avenue

Project Details Location:Cavendish Avenue, London Project Type: Restoration, Bespoke Moulding

-

Soho House, Dean Street

Project Details Location:Dean Street, London Project Type: Restoration, Bespoke Moulding, lime plastering